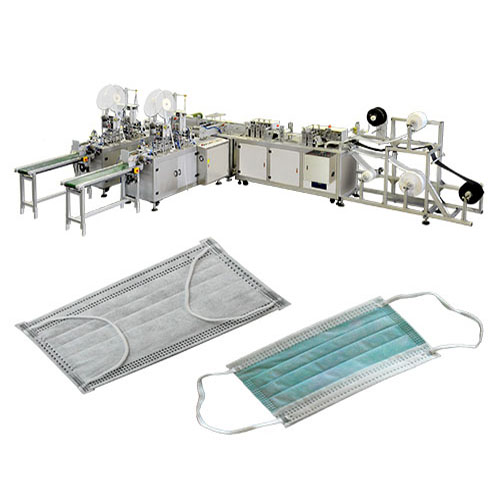

I. Automatic Blank Mask Making Machine;

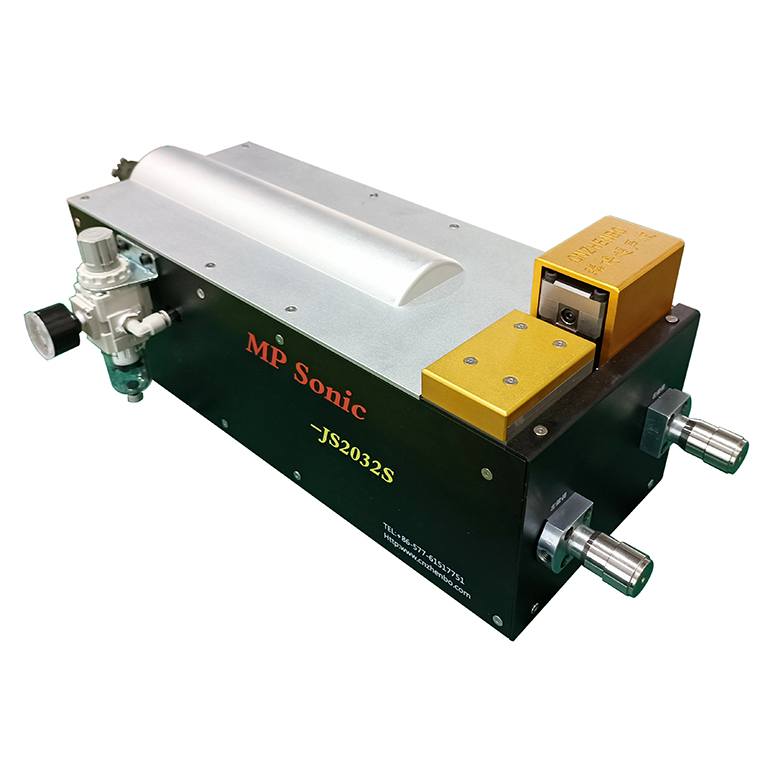

I-1. Application: IBM-BM100 is an automatic blank mask making machine which finishes fabric folding, nose wire inserting, fabric sealing by and mask cutting by automatic running. Machine converting is driven by motor with stepless regulation. Machine production capacity max to 135PCs/min in quality, and it is regulated basing on actual condition depending on fabric specification and mask size. Two sets of ultrasonic system in 20KHz are applies to seal fabric layers together at design area.

I-2. Main Technical Parameters:

1. Electric source:Single phase 220V 15A

2. Dimension:3680*700*1500mm(L*W*H)

3. Capacity:80~135 pieces per minute

I-3. Specification and range of mask:

1) Length of mask:120~210mm

2) Width of mask:100~150mm

3) Length of nose wire:100~140mm

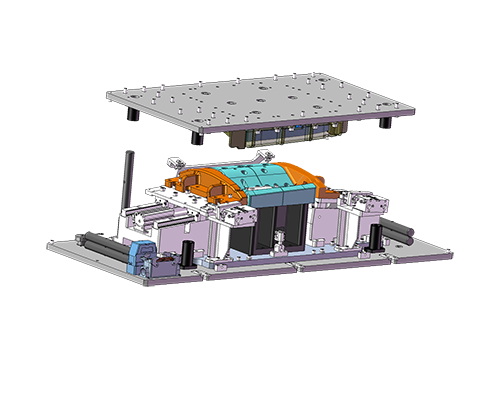

II. Automatic Inner Earloop Welding & Edge Bonding Machine.

II-1. Application: Automatic inner earloop welding machine & edge bonding machine is applied to attach earloop onto blank mask and seal non-woven tape onto two longer edge to bond edge by ultrasonic systems. Three sets ultrasonic system in 20KHz are applied, two of which are applied to spot weld earloop while the other one is applied to seal edge bonding. During machine running, masks are conveyed by trays automatically. PLC is applied to control sequence and optical sensors are applied to detect masks.

II-2. Technical Parameters.

1) Electric source:Three-phases 380V, 50-60Hz

2) Compressed air:0.6~0.8MPa

3) Dimension:2160mm*900mm*1600mm(L*W*H)

4) Capacity:50~60piece per minute

II-3. Specification and range of mask:(Adult, Child)

1) Length of mask blank:175mm (for adult); 145mm (for child)

2) Width of mask blank:90~95mm

3) Length of ear-loop:for Adult-170mm(max including welding spot)

for Child-150mm(Max including welding spot),adjustable according to client’s requirements

4) Distance of ear-loop welding spot:80mm

5) Width of edge material:20mm

6) Edge material ring:inner diameter70mm,outer diameter max to 600mm

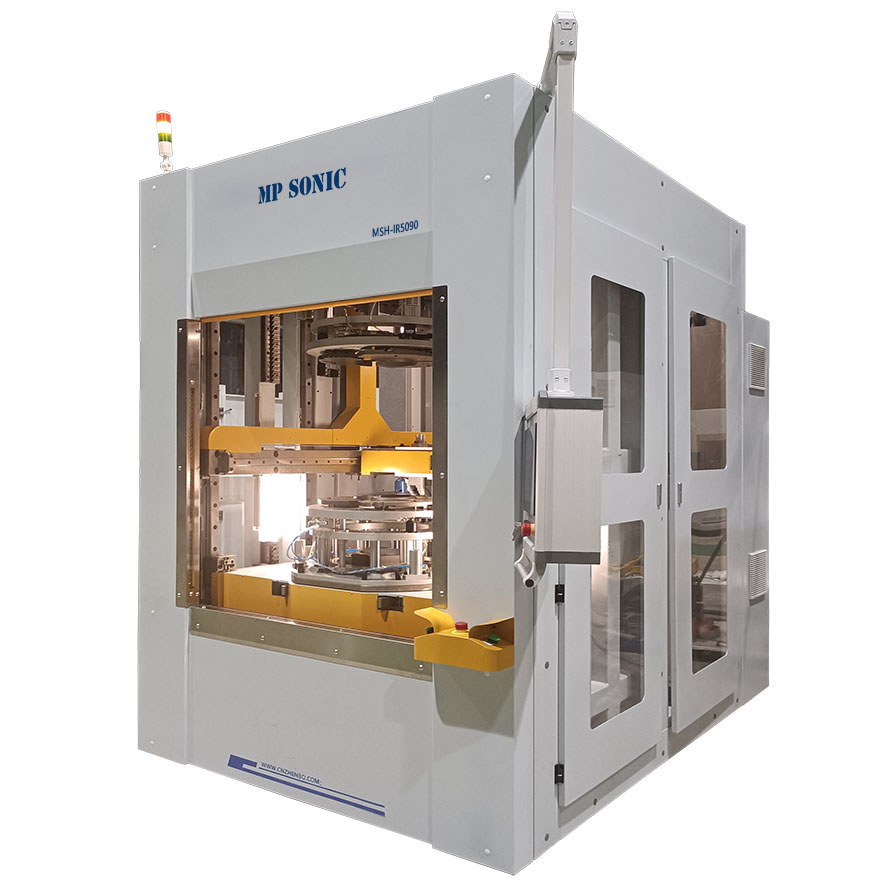

III. Automatic Outer Earloop Spot Welding Machine

III-1. Application: Automatic outer earloop spot welding machine is applied to attach earloop onto blank mask two sets of ultrasonic system in 20KHz. During machine running, masks are conveyed by trays automatically. PLC is applied to control sequence and optical sensors are applied to detect masks.

III-2Technical parameters:

1) Electrical source: Three phase 380, 50~60Hz

2) Compressed air:0.6~0.8MPa

3) Dimension:1800mm*900mm*1850mm(L*W*H)

4) Capacity:50~100piece/minute

III-3Specification and range of mask:(Adult, Child)

1) Length of mask blank: 175mm(adult), 145mm(child)

2) Width mask blank: 90~95mm

3) Length of ear-loop: For adult-170mm(max , including welding spot)

For children-150mm (max, including welding spot), adjustable as requests.

4) Width of welded ear-loop: 80mm

Download: Automatic Medical Mask Line

VIDEO

English

English