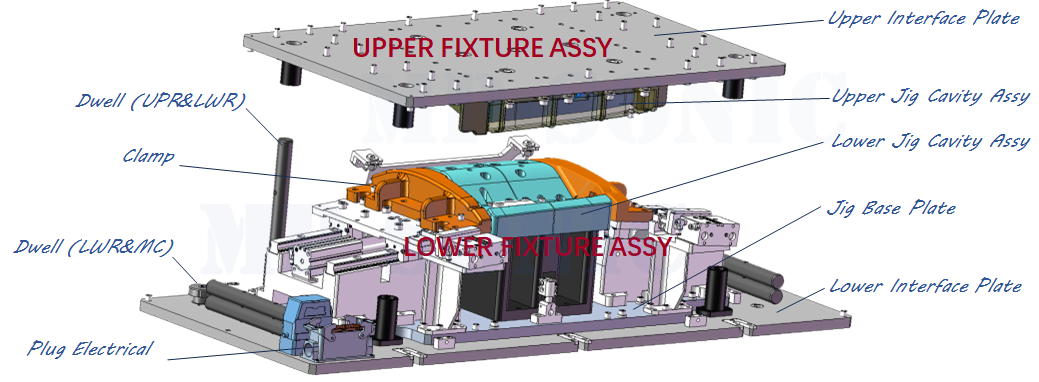

Vibration welding tooling, means fixtures applies for vibration welding, which act the function of holding & positioning during vibration welding. Vibration welding tooling should be designed as per the requirement as well as the design of plastic parts to be welded. Vibration welding tooling consists upper fixture assembly and lower fixture assembly. MP Sonic provides service of designing and manufacturing for clients.

The design of vibration welding tooling involves:

1. Machine specification mainly includes fixture interface plate size and vibration loading ability for upper jig weight;

2. Parts measurement and construction which mostly concerned the fixture construction design for parts loading & unloading in easy operation, positioning as well as the strength of fixture material requested;

3. Parts material which mostly concerned to welding tooling material selection, material process procedure, construction design and machining procedure, etc.

Auxiliary function of Tooling:

1. Vacuum to hold parts in position, especially need to be applied in upper fixtures since pneumatic forced clamps should not be designed on upper fixture because of easy damage by vibration during operation.

2. Clamp which is sliding block design by external force (normally by pneumatic cylinder) normally are applied to allow plastic parts to be welded in complex geometric shape design into lower fixture cavity.

3. Clips by pneumatic circuit to hold part in lower fixture.

5. Ejectors in lower fixture help unloading welded parts.

6. Parts detector to confirm parts presence or right location by manual loading.

7. Parts location rectification mechanism after manual loading and before welding.

Main Material of vibration welding fixtures;

1. Aluminum: the most fixture elements are made of aluminum.

2. Steel: for vibration welding tooling parts which requests high strength according to parts material and structure design. For example, to maximum the duration of teeth engraved on base jig, it should apply steel in high strength. But steel density is higher than aluminum or resin, by the same volume of jig design, steel material will bring higher loading to vibration welding machine.

3. Epoxy resin applied to protect welded part surface from damage.

4. Rubber sticking leather Epoxy resin applied to protect welded part surface from damage.

Requirement to vibration welding fixture:

1. Strength ensure reliability and duration working in strange vibration by vibration system of machine under high pressure.

2. Protect parts, especially it should keep surface A from any mark during welding.

3. Ensure enough support at the back of welding area under high pressure to ensure strength and moreover air-tightness of welding result.

4. Fit for parts variation: vibration welding fixture design must consider the parts variation existing to ensure the reliable welding result.

5. Possibility in operation: the tooling design should fit for complex parts design and ensure the possibility of parts loading & unloading.

Structure of vibration welding fixture:

Read more about MP Sonic Vibration Welding Machines

Samples of Vibration Welding Tooling