Vibration welding is a technology frequently

applied in fuel engine system. Mostly, linear vibration is applied to weld engine

air inlet manifold, valve cover, resonancer, oil pan, pipe filler, air-duct, etc.

Because of high temperature of engine during

automotive running, as well as also considering the reliability of engine

system, the material or welded parts mostly is PA+GF, for high hardness and

high temperature resistance. The welding of engine parts mostly requests

strictly in air-tightness, strength and cleanness inside of parts.

Besides the auxiliary function of welding

fixture to engine system parts which mostly involved in parts design, the

material of fixture as well as the process treatment to material is very

important to the welding result, fixture reliability and duration because the

hardness of PA+GF.

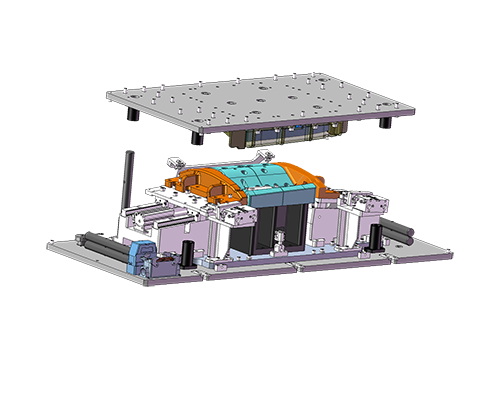

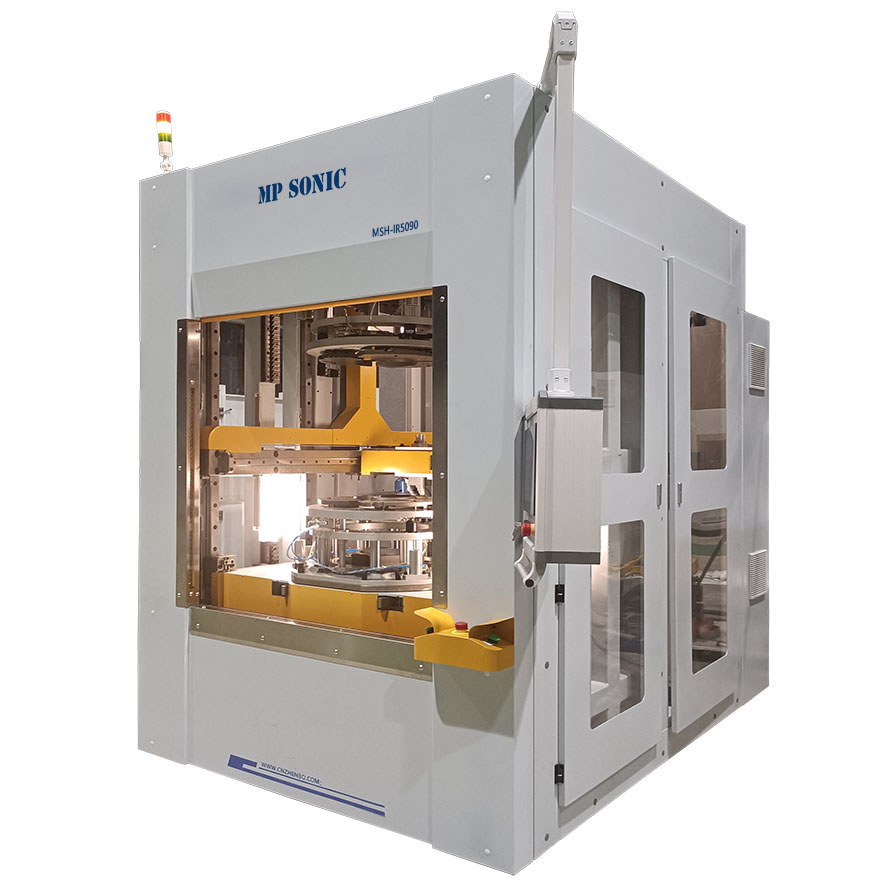

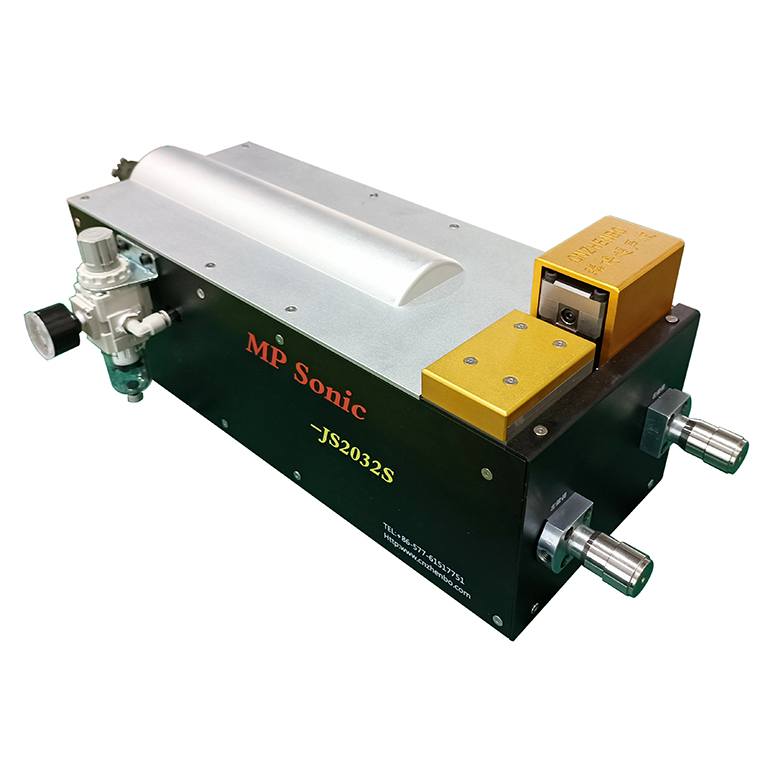

MP Sonic designs linear vibration welding tooling

for customers according to parts design and machine specification. To ensure

the welding result, it is necessary to send MP Sonic 3D data and machine specification

information for analysis before the design of parts is finally frozen.

Cases Sample

Engine Air Inlet Manifold Fixture

Engine Valve Cover Welding Fixture

Resoancer Welding Fixture

Air Manifold Welding Fixture

Fuel Filler Welding Fixture

Oil Pan Welding Fixture

English

English