Super High Frequency Vibration Welding Technique

by Alex Lee Mobile/Wechat/WhatsApp: +8615918523336

Super-high frequency linear vibration friction welding technique is the newest vibration welding developed by CNZHENBO | MP Sonic, which applies vibration frequency up to 365Hz. The machine by this technology has been certificated as “ The 1st Set of Manufactured Products” by Department of economy and information technology of Zhejiang Province.

With the super have vibration frequency,

system achieve enough friction energy to melt plastic material and form

thermoplastic welding in vibration amplitude as low as 0.3mm, which with the advantages of

clean vibration welding performance, high welding ability and small limit to

parts geometric design.

Check MSV-SF Series Super High Frequency Vibration Welding Machines

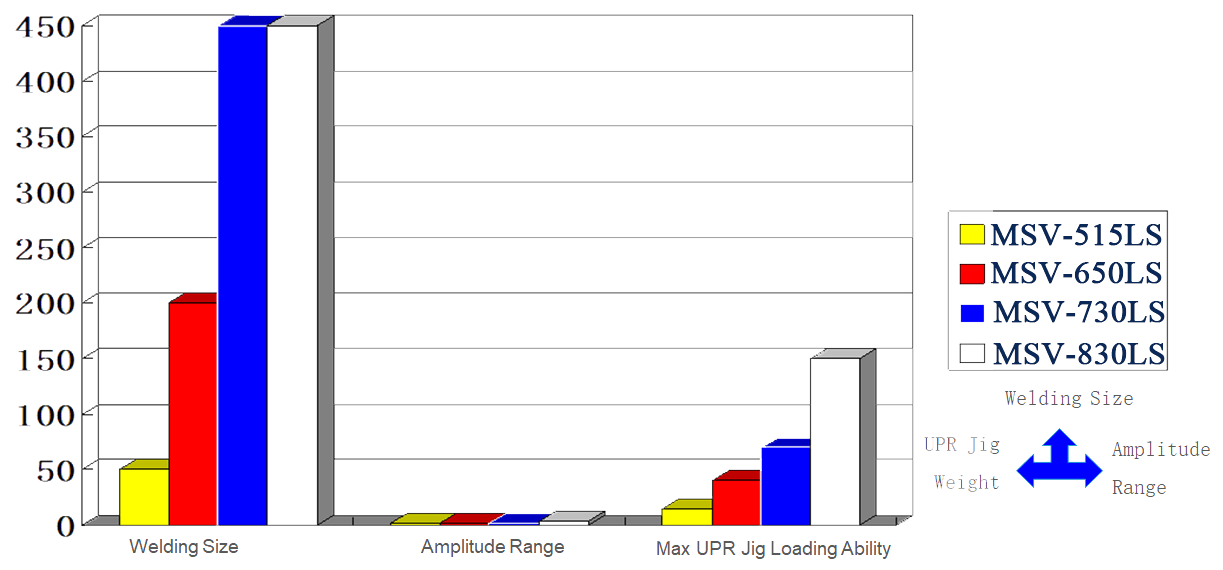

I. The Key Technical Parameters for Vibration Welding

The critical technical parameters for vibration welding:

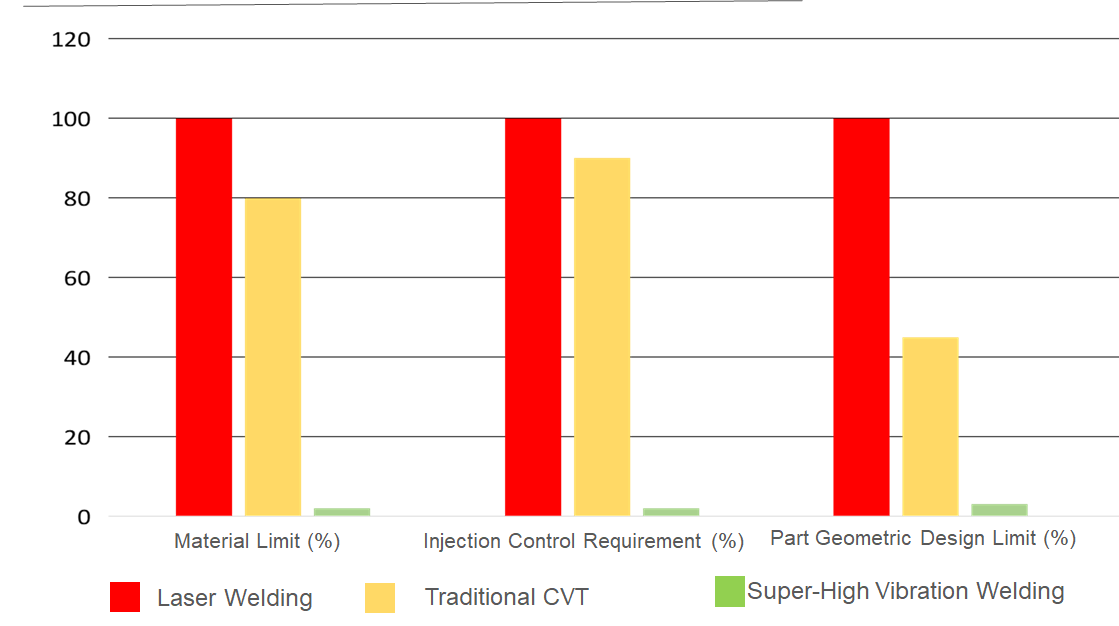

The latter page will show the advantages of super-high frequency vibration with data comparation between super-high frequency vibration welding, traditional vibration welding / Traditional CVT (Pre-heating Type Clean Vibration Technique) and laser welding.

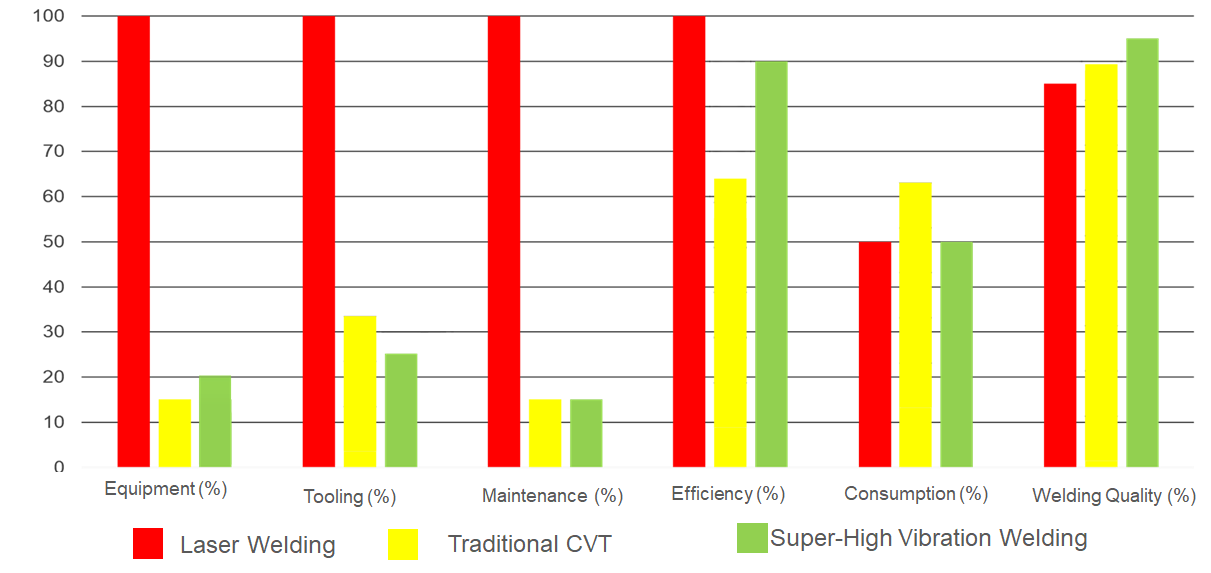

III. Comparation—Production Cost

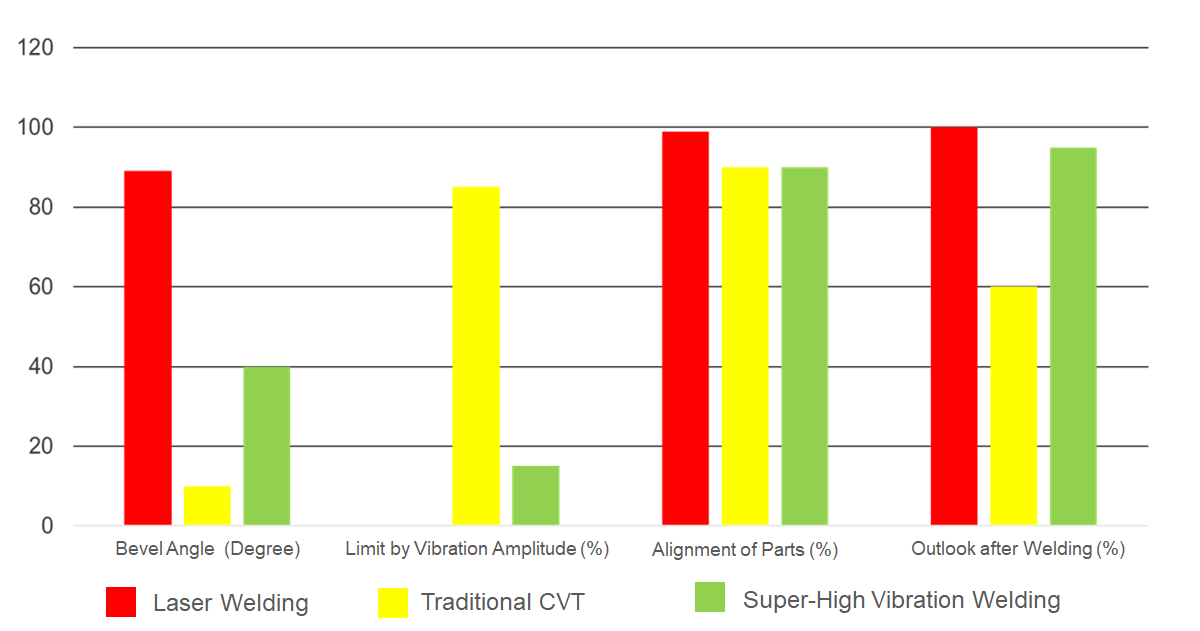

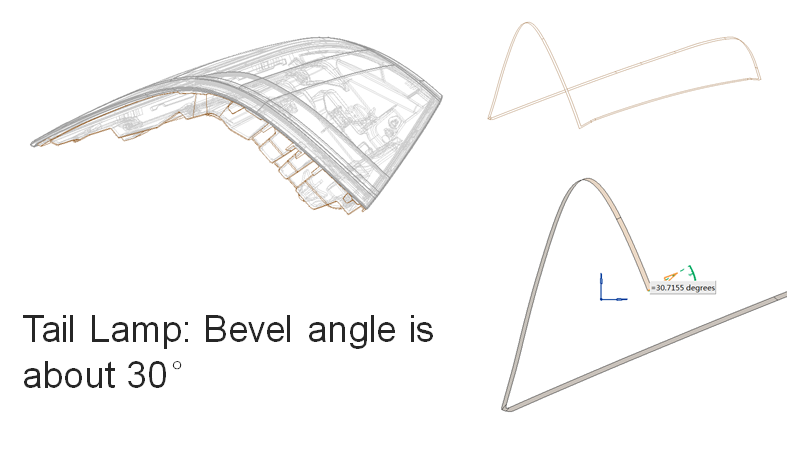

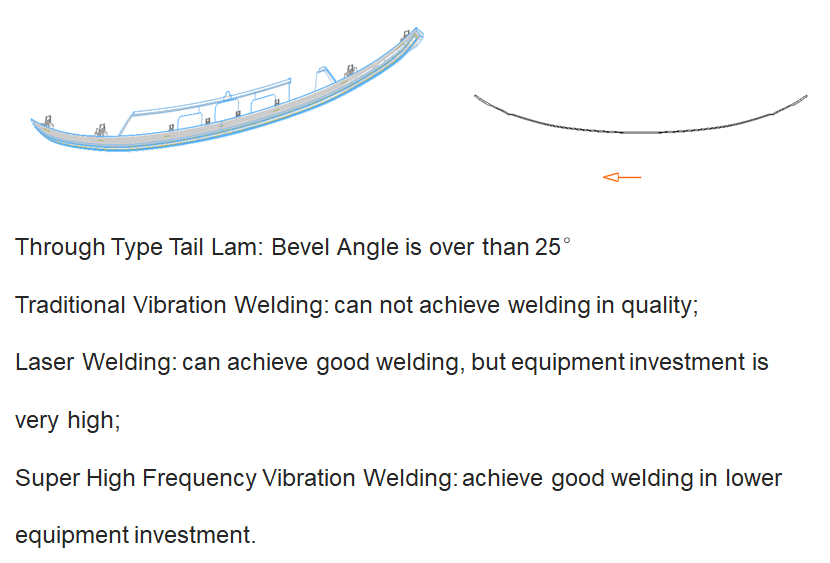

IV. Comparation—Limit to Application

V. Advantages of Super-high Frequency Vibration welding

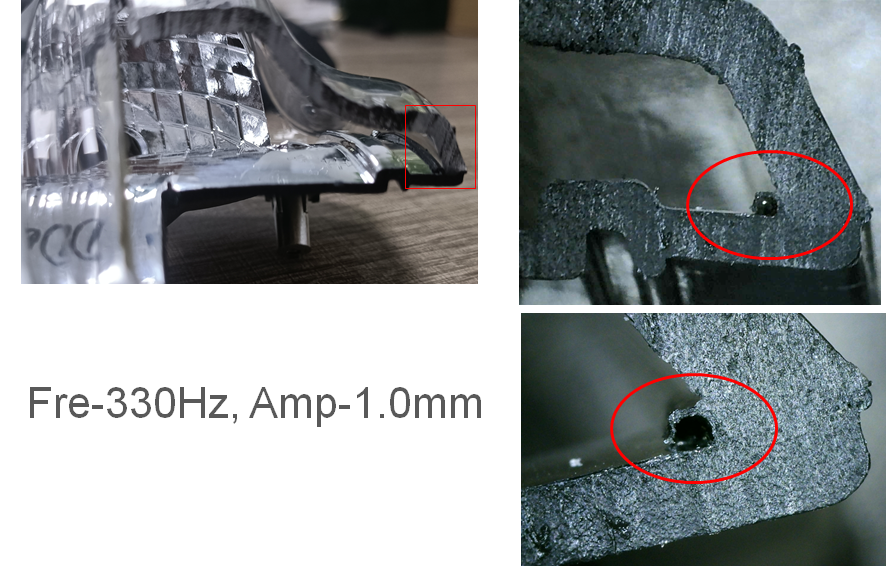

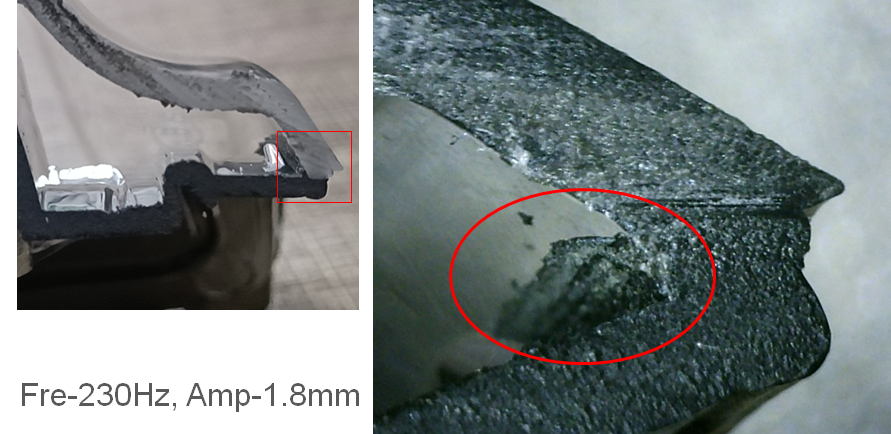

E.Small vibration amplitude friction welding, avoiding material dust cased, achieving clean vibration welding without preheating, welding quality is high, performance is stable.

VIII. How to Select Vibration Welder Specification