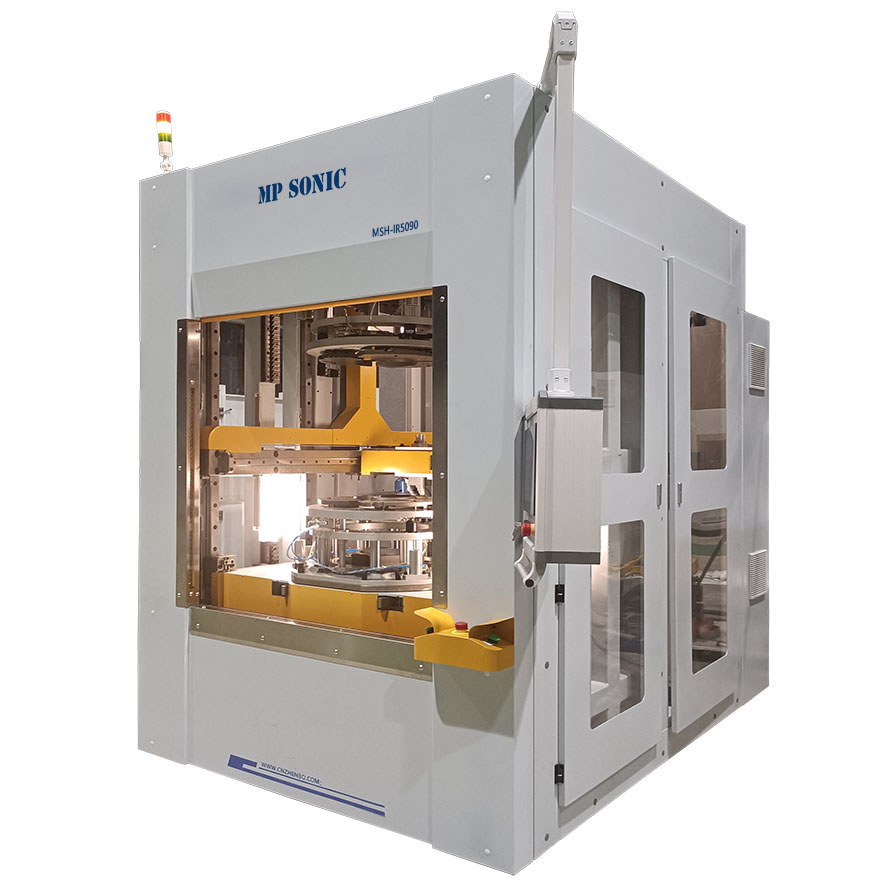

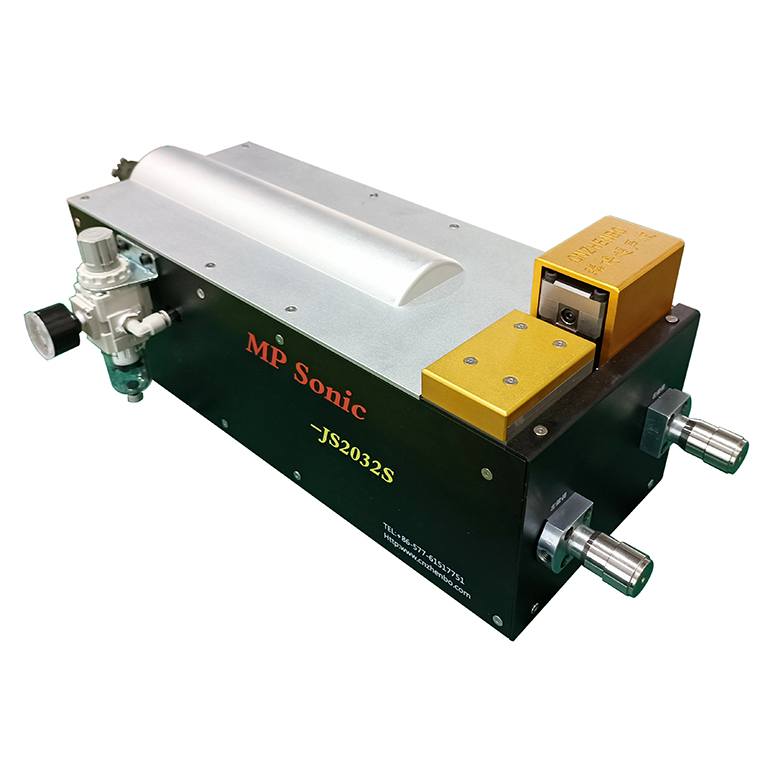

Sero Ultrasonic Welder

Servo ultrasonic welder is newly designed ultrasonic plastic welding machine designed by MP Sonic.China, CNZHENBO, with multiple advanced function, including timing weld control, pressure force trigger control, depth control, energy control, welding process visualization graph supervision, amplitude control, welding record, multiple protection, etc.

Machine applies MP Sonic advanced IGBT ultrasonic system to finish welding. Servo motor is applied to force and control welding, welding depth is close-loop controlled by in high precision.

English

English