Features:

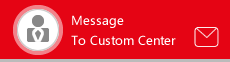

1. Machine applies pneumatic cylinders to control welding action, independent pressure control system is applied to each cylinder to ensure fast action and stable pressure;

2. It applies regulator controlled PID or PLC Temperature module controlled PID (select one from two methods), ensuring high precision, stable & accurate temperature for melting;

3. 8 temperature control zones provided (enhance to 8 zone from 4 zones in free), upper * 4zones & lower*4zones;;

4. HMI supervise the heater state, if any hear is not working, the relative temperature zone ID will indicated on HMI.

5. Formula system: machine system can store at least 80 sets of welding parameters. When welding different parts, it can recall relative parameters from formula system directly with out change parameter;

6. Machine system is quipped with data memory system for welding operation record and error/alarm record for further history check;

7. Machine system designed with I/O supervision page and self-check system. It can check machine state in time, and if any error happen, machine will make alarm, and related fault message will show on HMI and put into memory;

8. Authorization password system is designed to set account ID for different level operators;

9. Human safety: design optical fence and automatic door at front, design sensor detected safety door for others side;

10. Machine designed vacuum, pneumatic clamp, sliding, etc function help easy operation and ensure welding result;

11. Injection function is designed to help unloading parts after welding;

12. PokaYoke function is designed in machine system to avoid operation with missing parts in right position

13. CNZHENBO|MP Sonic I-Could system for remote service in easy and fast service.

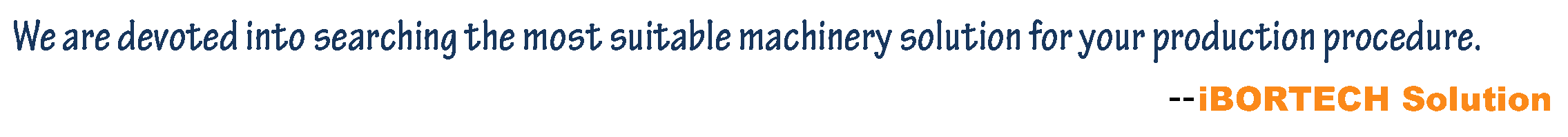

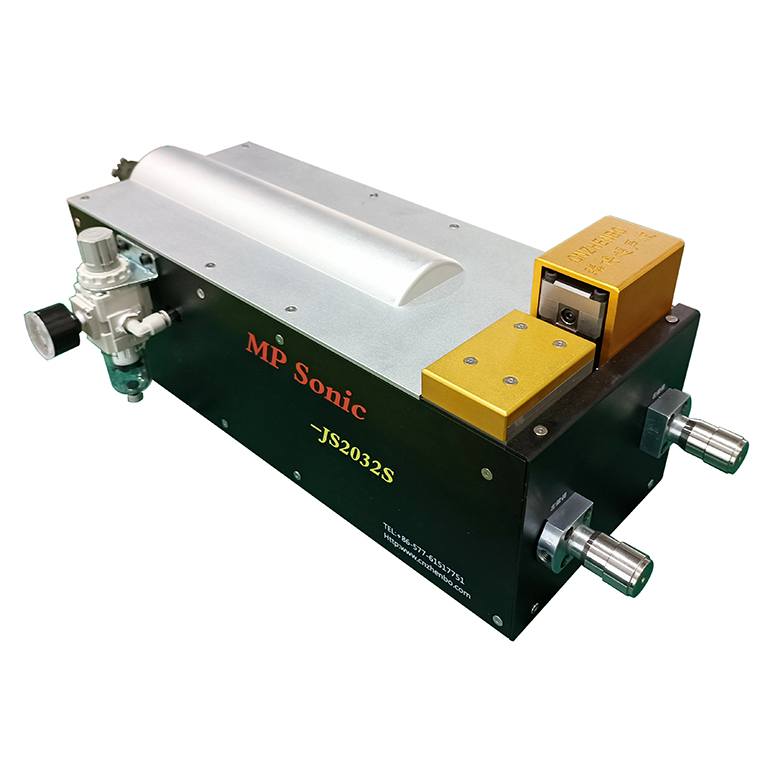

II. Machine Consturion:

III. Specification

|

Weight:1.2T

|

Power Supply:380V 50HZ

|

|

Dimension:1750*1550*2600mm

|

Machine Control:HMI

|

|

Upper Jig Plate:660*420mm

|

|

Hot Mould Plate:660*400mm

|

Max Power:20KW

|

|

Max Welding Area:600*400mm

|

Control Voltage:DC24V

|

|

Optical Fence Protect Height:440mm

|

Temp Zone: 2+2

|

|

Upper Jig Move Distance:350mm

|

Sensor Detection Distance:38mm

|

|

Lower Jig Move Distance:300mm

|

Working Condition

|

|

Hot Platen Move Distance:450mm

|

Air Supply:0.5--0.7Mpa

|

|

Air Supply Pipe:Ф12

|

Max humidity:≤80%RH

|

|

Paid Option:

Auto Jig Loading System;

SPC; UPS; Vacuum Pump

|

Room Temp:-10--60℃

|

|

Noise:≤85dB

|

English

English